Poor water quality affects the reprocessing of sterile goods and medical devices.

The number of outpatient clinics for operations is growing steadily in Germany. The availability of sterile instruments is essential for carrying out planned operations. The locally available water quality can vary greatly depending on the location of the medical care centre.

It is important to adapt the water treatment to the local water quality, as this cannot be transferred from one location to another.

There are 3 parameters to monitor.

1. silicate monitoring

Silicate monitoring plays a crucial role in the water treatment process for sterile medical devices in outpatient clinics.

Among other things, the water used contains silicates, which are responsible for the formation of silicate clouds and pitting corrosion on the instruments.

In order to ensure the quality of sterile medical devices and minimise the risk of infection for patients, it is essential to remove silicates from the input water as part of the water treatment process and to comply with the requirements of the DGSV guidelines and the AKI. Careful monitoring of silicate levels is therefore essential.

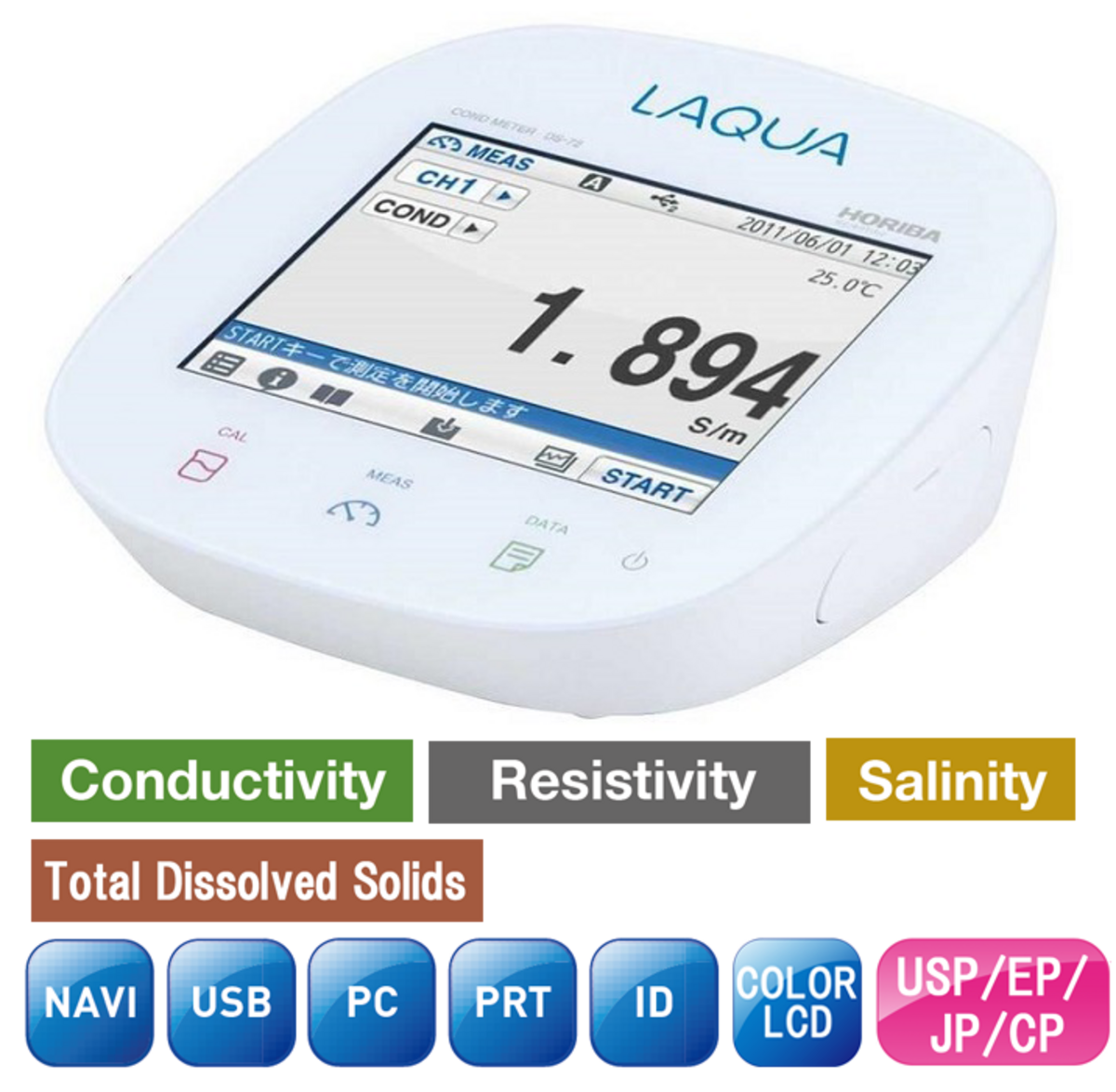

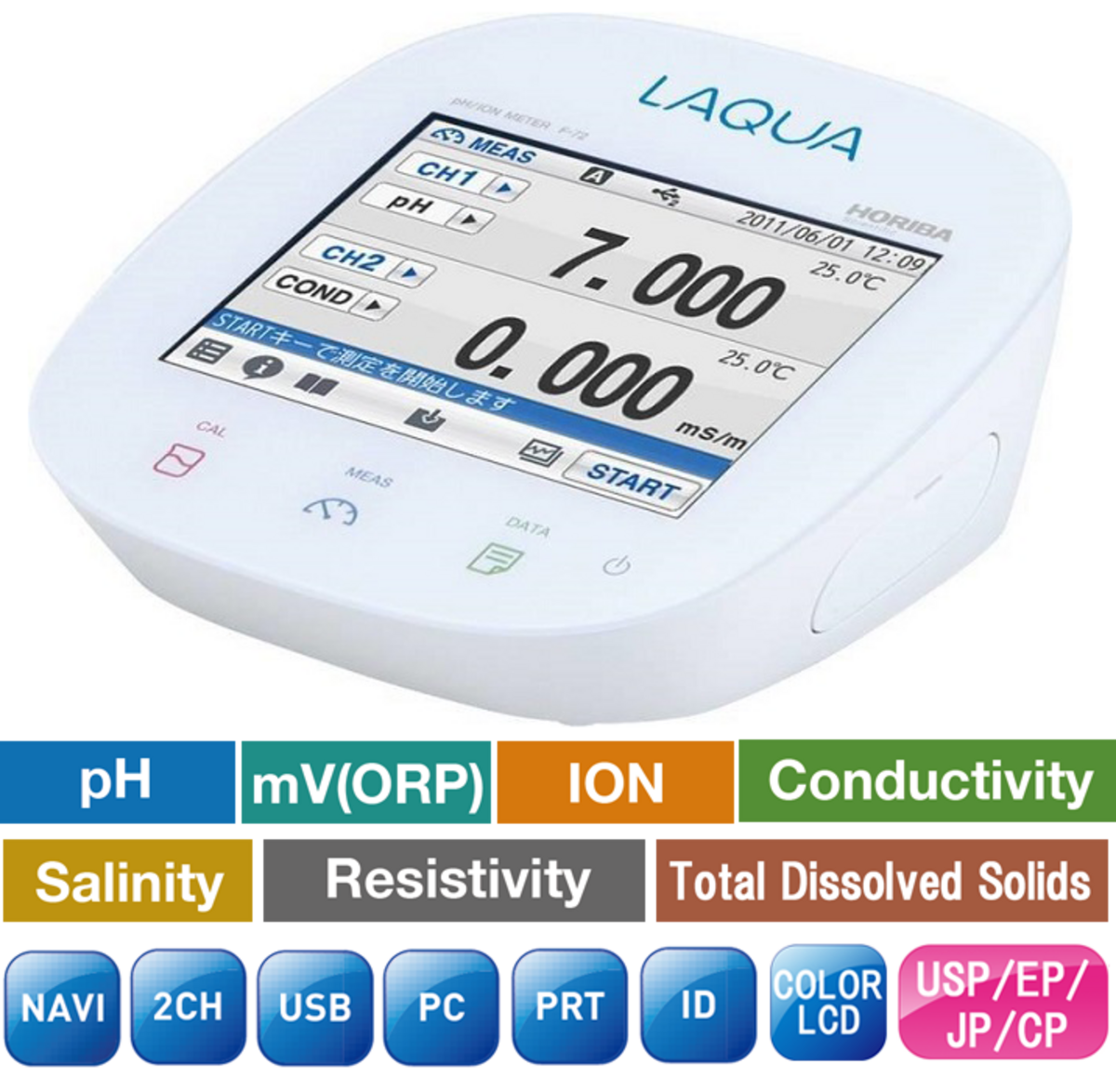

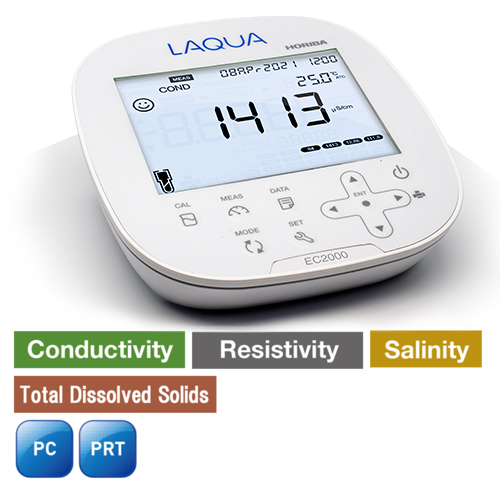

2. conductivity monitoring

Conductivity measurement is another important aspect of process water treatment in clinics to protect the instrumentation. The conductivity of water is a property that indicates the general quality of the water. Various dissolved substances (primarily salts) in the water are producers of conductivity, so the conductivity value is a good indicator of the purity of the water.

3. residual hardness monitoring

In addition to silicate & conductivity monitoring, residual hardness measurement is also of crucial importance. The hardness of water arises from dissolved salts, which in natural waters are mainly formed from magnesium and calcium hydrogen carbonate and sulphate, which are dissolved from the soil and/or aquifers. The concentration of salts therefore influences the hardness of the water.

Filter products